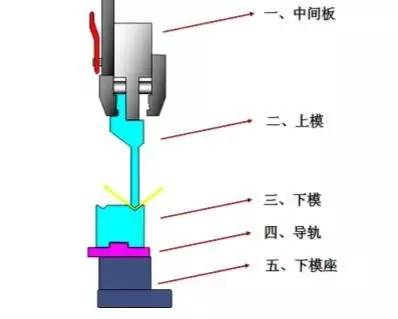

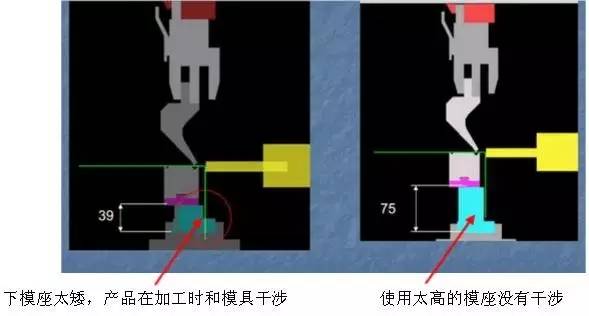

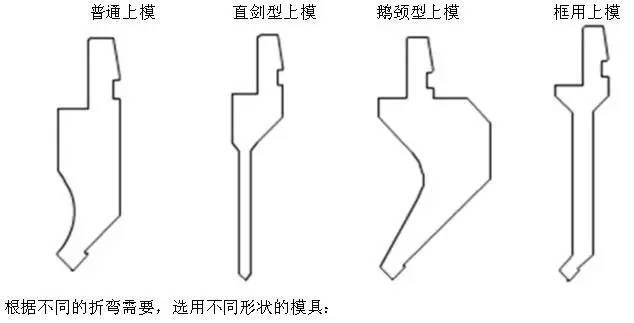

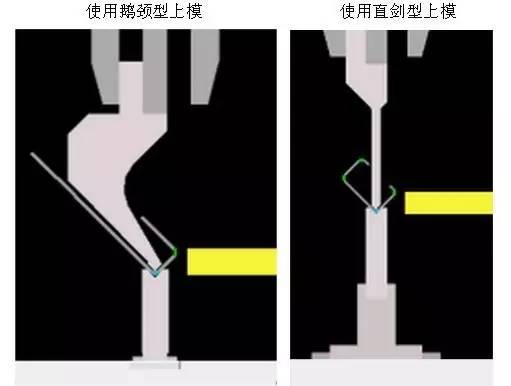

1. The general mold of the bending mold is divided into the middle plate, the upper mold, the lower mold, the guide rail, the lower mold seat, etc. This type of mold is highly versatile, and most of the processing can be completed.2. Selection of bending molds Different molds are required to process different parts. First, you must understand the processing parameters of machine tools and molds before you can choose molds that match each other.Machine parameters include: stroke, processing capacity, opening height, intermediate plate type, etc.; Mould parameters include: upper die shank type (matching with the intermediate plate), pressure tonnage (maximum bending pressure), etc.; A selection of machine parameters 1. Selection stroke of mold height (mm) = opening height - intermediate plate height - upper mold height - lower mold seat height - (lower mold height - 0.5V+t) t is the thickness of the sheet (mm) selected in the lower mold seat At the same time, it should also be noted that the lower die base has various heights, and the die bases of different heights are used for different processing.Different die combinations can be used to obtain different die combination heights for machining different parts.B about the selection of mold parameters 1. Upper mold handle form The upper mold handle has 3 forms to match different intermediate plates 2. The shape of the upper mold commonly used standard shapes The upper molds are: 3. The upper mold tip R angle and tip angle The commonly used tip R angles for the upper die are: (1) 0.2R (2) 0.6R (3) 0.8R (4) 1.5R (5) 3.0R Select the appropriate tip R: generally use R0.6 below 3mm.The tip angles of the standard upper die are: 90 degrees, 88 degrees, 86 degrees, 60 degrees, 45 degrees, 30 degrees; etc.The included angle of the mold should be smaller than the processing angle. For example, we bend the workpiece at 90° and use a mold with an included angle of 88°.4. The lower mold form The general lower mold has the difference of single V and double V. In these two types, there are divisions and whole sections. Different mold types are suitable for different processing needs.Generally speaking, the single-V mold is more widely used than the double-V mold, and the divided mold is more widely used than the entire mold.The lower molds used by our company are generally double V and triple V.5. The relationship between the V-width and the included angle of the lower die V-slot and the material thickness (T): The V-slot angle of the lower die is the same as that of the upper die.Huizhou Shunqiang Electronics Co., Ltd. Tel: 0752-5866663 Fax: 0752-5873686 Contact: Xu Guoming Mobile: 13715334662 Email: everwinmold@163.com Website: http://everwinmold.robot-china.com Shunqiang Electronics: https: //shunqiang.diytrade.com WeChat ID: kennethchui888 No. 33, Huling North Road, Baigang Village, Xiaojinkou Town, Huizhou City Introduction: Huizhou Shunqiang Electronics Co., Ltd. was established on July 18, 2006, and its main business scope is production and sales Mobile phone charger inserts, switches, sockets, molds, hardware products, die-casting molds, die-casting products, plastic molds, plastic products, spare parts processing, CNC processing.Precision mold production inclined roof with row position, case of surrounding sliders, car lamp mould, inner inclined roof in explosion position plus reverse position elbow core pulling mold, inclined roof on inclined roof, inclined drawing structure mold, secondary sliding The basic knowledge of block mold slider with slider mold, slider inclined top mold, refrigerator drawer, automatic flip structure stamping mold is fully understood!One ring of continuous mode, golden ten thousand taels!