In our plastic mold design industry, there are many types of mold structures. For general mold designers, ordinary sliders and inclined roof structures are familiar to everyone, and they can design them, but for some more special and typical molds Structure, there will be a feeling of nowhere to start. Today I will explain to you the key points of the design of the screw thread mold structure. I hope that the mold design enthusiasts of Guangxi University and the partners who want to know more about the screw thread core structure will be inspired:

Plastic product threads are divided into two types: external thread and internal thread. For external threads with low precision, Huff blocks are generally used, while most internal threads require thread unloading devices. Here is a brief introduction to the internal thread demoulding method and the introduction of gear calls:

1. According to the action mode:

① The thread core rotates, and the push plate pushes the product away;

②The thread core rotates and retreats at the same time, and the product naturally detaches.

2. Divided by driving mode: There are generally two types of extraction molds: one is that the cylinder drives the rack to move, the other is the motor drives the chain to move. The following picture shows the cylinder drives the rack to twitch:

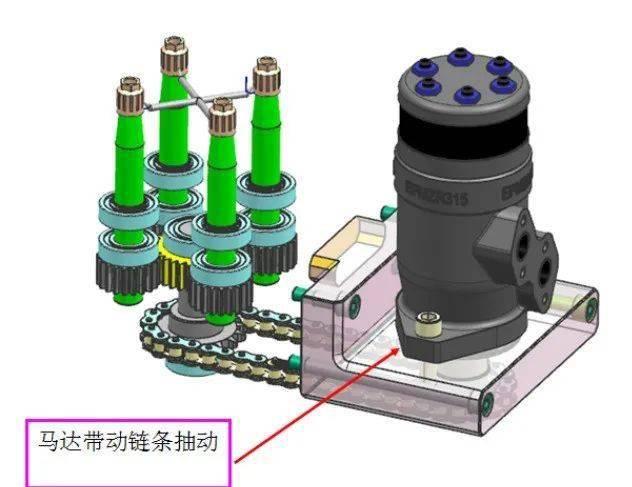

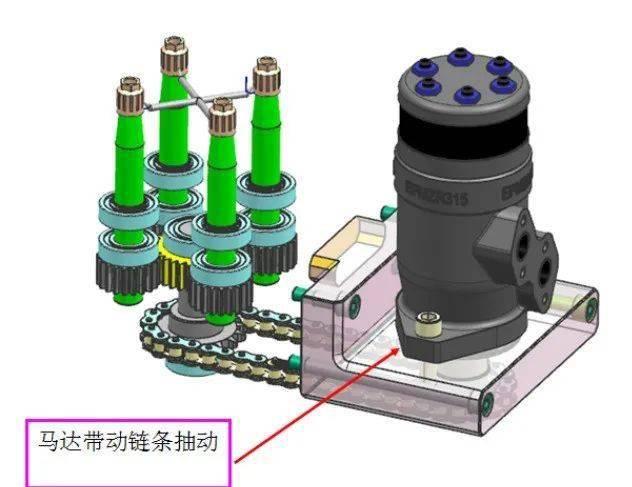

The following picture shows the chain twitch driven by the motor:

3. Twitching principle of the thread mold: the tooth distance of the braces and braces must be the same as that of the product, and the braces will act as a guide. The cylinder drives rack 1 to move-rack 1 drives gears 2, 3 to rotate-gear 3 drives gear 4 to rotate-gear 4 and the screw are positioned to rotate together, as shown in the following figure:

4. When designing the thread mold, you must know the pitch. The definition of pitch is the vertical movement distance of the screw when it rotates one circle, as shown in the following figure:

5. The pitch of the glue position of the product and the pitch of the screw must be the same, otherwise the product is easy to drag.

6. How to call gears and racks: Hu Bo can call gears and racks externally. According to the product ranking in our mold, we can determine the indexing circle required by our gear directly, and then the gear modulus is the same. You can call up the gear as shown in the figure below:

7. How to call the rack: The rules for using Hu Bo's external rack are also to follow the formula (modulus X number of teeth = index circle diameter)

8. If you want to design a thread mold, you must understand the relationship between rack and pinion. The following figure shows the relationship between rack and pinion and the relationship between each gear:

9. The calculation of the number of exit turns required for the product and the length of the rack: the number of turns of the tooth is 5, then the screw exit requires at least 5 turns. The screw retreats 6 turns. Then you can calculate the rack twitching distance according to the previous page: