Vacuum heat treatment refers to the process of placing mold parts in vacuum heat treatment equipment for heating, heat preservation and cooling. It is one of the current advanced mold heat treatment technologies. As the requirements for mold quality are getting higher and higher, it is difficult for general heat treatment to meet technical requirements. After vacuum heat treatment, the surface of the mold is not oxidized or decarburized, the quenching distortion is small, the surface hardness is uniform, the use performance is improved, and the service life of the mold is generally increased. , Generally can be increased by more than 30%, and vacuum heat treatment can reduce the machining allowance (grinding or polishing) by 1/3~1/2, thereby improving production efficiency and reducing mold manufacturing costs. Vacuum heat treatment is especially suitable for molds with high precision, required size and stable performance. Mold vacuum heat treatment technologies include: vacuum quenching, vacuum tempering, vacuum carburizing, vacuum nitriding, vacuum metalizing, etc. Figure 1 is the mold vacuum heat treatment equipment, and Figure 2 is the mold photo.

Figure 1 Mold vacuum heat treatment equipment

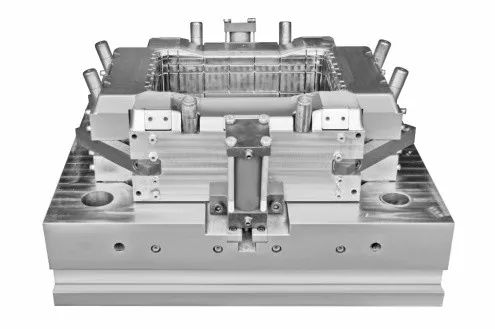

Figure 2 Mold photo

1. Vacuum heat treatment process parameters

(1) Vacuum

The degree of vacuum directly affects the roughness of the mold surface, thereby affecting the surface quality performance. In order to prevent the volatilization of the alloy elements on the mold surface, a reasonable vacuum degree should be selected. The corresponding relationship between the vacuum degree and the heating temperature during the vacuum heating of alloy steel molds is shown in the table 1.

Table 1 Correspondence between vacuum degree and heating temperature

Heating temperature/℃

≤900

1000~1100

1100~1300

Vacuum degree/Pa

≥0.133

1.33~13.3

13.3~665

(2) Preheating temperature

When the heating temperature of vacuum heat treatment is 1000~1100℃, preheat once at 800~850℃; when the heating temperature exceeds 1200℃, molds with simple shapes can be preheated once at 850℃, larger or complex moulds It should be preheated twice at 500~600℃ and 800~850℃.

(3) Heat preservation

1) Heating temperature. The heating temperature of vacuum quenching generally takes the lower limit of salt bath furnace and air furnace. The heating temperature of vacuum tempering, vacuum annealing, vacuum solution treatment and vacuum aging is generally the same as that of conventional heat treatment.

2) Holding time. Under normal circumstances, the vacuum heating time is 6 times that of the salt bath furnace and 2 times that of the air furnace. The empirical formula is τ = KB + T, where τ is the heating and holding time (min), K is the holding time coefficient (min/mm), B Is the effective thickness of the mold (mm), and T is the time margin (or fixed time) (min). The K value and T value can be found in Table 2.

Table 2 Calculating parameters of mold vacuum quenching holding time

Steel

Holding time factor

K/min·mm -1

Time margin

T/min

Remarks

Non-alloy tool steel

1.9

5~10

Preheat once at 560℃

Low alloy tool steel

2.0

10~20

Preheat once at 560℃

High alloy tool steel

0.48

20~40

Preheat once at 560℃ and once at 800℃

High speed steel

0.33

15~25

Preheat once at 560℃ and once at 800℃

2. Vacuum quenching of the mold

(1) Warm up

Low alloy steel (40Cr, 60Si2Mn, etc.), medium alloy steel (CrWMn, 9CrSi, 5CrNiMo, etc.) can choose two-stage heating (such as 650℃ preheating → 850℃ quenching heating); high alloy steel (H13, Cr12MoV, etc.) can be selected Three-stage heating (such as 650°C preheating→850°C preheating→1030°C quenching heating).

(2) Selection of heating and holding time

The holding time must ensure that a certain amount of carbide is fully dissolved, increase the alloy content in the austenite, and provide a guarantee for a more obvious hardness rise during the secondary hardening peak temperature tempering, and it must not produce overheating that affects the quality of the mold.

(3) Cooling method

The vacuum quenching of die steel can be oil quenching, gas quenching, water quenching, nitrate quenching, etc. All alloy die steels can be subjected to vacuum oil quenching to obtain a bright surface and reasonable performance. Compared with air quenching, it is easy to obtain high toughness and strength due to the fast oil cooling speed. Air-cooled quenching can obtain smaller quenching distortion.

The vacuum quenching cooling method should be selected according to the shape, material, size, technical requirements, etc. of the mold, see Table 3 for details.

Table 3 Selection of vacuum quenching cooling method

cooling method

Scope of use

Vacuum oil quenching

Suitable for die steel such as alloy tool steel, high carbon and high chromium alloy steel, high speed tool steel, etc., using special vacuum oil quenching. Vacuum oil quenching is especially suitable for molds that require high strength and toughness

Air-cooled

In order to reduce mold distortion, shorten the process cycle, and achieve clean heat treatment production, more and more air-cooled quenching is used internationally. Requirements for cooling rate: H13 (4Cr5MoSiV1) steel≥28℃/min, Cr12MoV steel≥17℃/min

1) 0.2MPa vacuum air quenching: that is, low pressure vacuum air quenching, the maximum cooling pressure of N 2 quenching is 0.2 MPa, and the purity of N 2 is above 99.95% (volume fraction). It is generally used for high-speed tool steels with low cooling speed requirements. And hot and cold working die steel

2) 0.6MPa high-pressure gas quenching: its N 2 quenching pressure is 0.6MPa, which is generally used for quenching of high-speed tool steel, high-carbon and high-chromium alloy steel, and part of alloy tool steel for making molds.

3) Ultra-high pressure gas quenching above 1MPa: generally used for all high-speed steel, hot work die steel, cold work die steel, Cr13 steel and some oil quenched alloy steels. Also suitable for quenching of large and medium-sized molds

Vacuum water quenching

Used for quenching and cooling of non-ferrous metals, heat-resistant alloys, titanium alloys, carbon steel, etc.

Vacuum nitrate quenching

Using nitrate salt for mold classification or austempering can reduce mold distortion, avoid cracking, prevent decarburization of high-strength structural steel, etc. The total cooling capacity of a static nitrate salt bath is equivalent to that of oil, and stirring can increase the salt bath’s performance. Cooling capacity, the general use temperature is controlled in the range of 160~280℃

Example: H13 (4Cr5MoSiV1) steel super large aluminum alloy die-casting mold (5t), using Ipsen's Super Turbo vacuum furnace to quench the heating temperature at 1000 ℃, after sufficient heat preservation, use 1.5 MPa nitrogen quenching to cool, stop cooling at 400 ℃ to enter Isothermal maintenance stage to reduce mold distortion and avoid cracking. In the end, excellent mechanical properties and minimal quenching distortion were obtained. The specific test results are shown in Table 4.

Table 4 Results of vacuum quenching of H13 steel mold

project

surface

Heart

Microstructure

small

Small (in quenched state)

Grain size/level

10~11

9

Tensile strength Rm/MPa

1287

1264

Yield strength ReL/MPa

1044

1019

Elongation after breaking A (%)

19.5

17.8

Reduction of area Z (%)

52.8

49.1

Impact absorption energy/J

262, 282, 279

221, 239, 238

(4) Vacuum tempering

The advantages of using a vacuum furnace (such as WZH series single-chamber positive pressure tempering furnace) for tempering: accurate and uniform temperature control; ensuring no oxidation during heating and holding; it can be slowly cooled with the furnace, or it can be inflated and quickly cooled. The cooling process can be filled with high-purity N2 or a mixture of high-purity N2 and other reducing gases (such as H2) to ensure that it does not oxidize or color during cooling.

The tempering heating speed is 0.8min/mm, and the core should be kept for at least 2h after reaching temperature. The tempering temperature depends on the hardness requirements. The first and second tempering are mandatory, and the third tempering depends on the technical requirements and final hardness, and can be omitted.

(5) The vacuum quenching and tempering process parameters of commonly used die steels are shown in Table 5.

Table 5 Vacuum quenching and tempering process parameters of commonly used die steels (GB/T 22561—2008)

(You can click to enlarge and watch)

3. Vacuum annealing of the mold

The vacuum annealing of the mold (module) is easy to realize heat treatment without oxidation and decarburization, which is beneficial to improve the surface quality and production efficiency of the mold, shorten the process cycle, and the mold surface can be bright and the microstructure is uniform.

(1) Ordinary vacuum annealing process

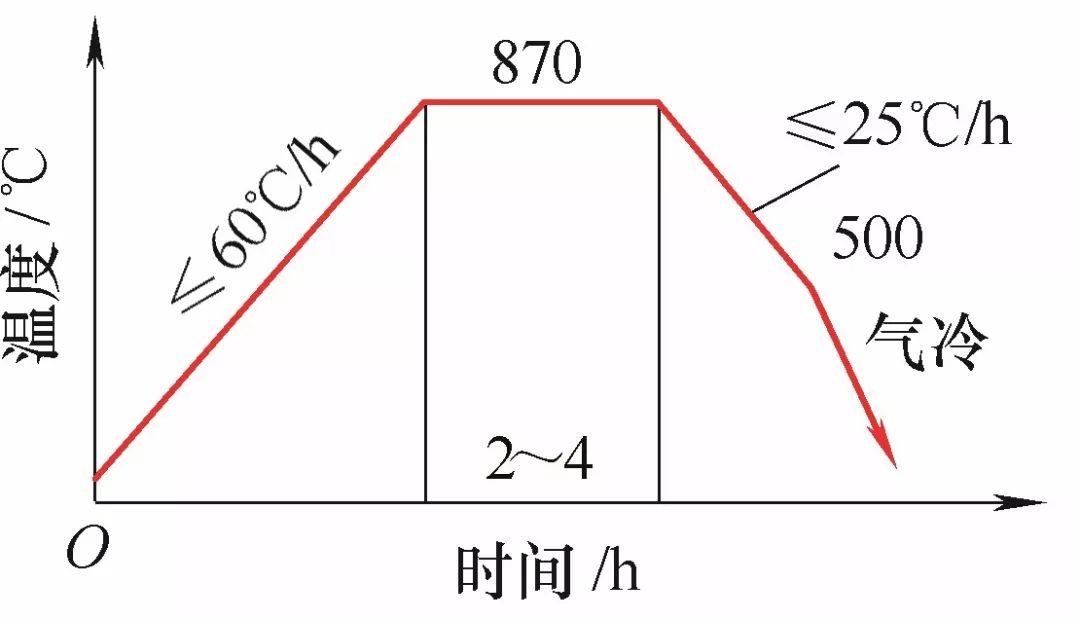

Figure 3 shows the normal vacuum annealing process of H13 (4Cr5MoSiV1) steel module. Mold annealing adopts vacuum furnace (such as WZT series single-chamber vacuum furnace, ultimate vacuum degree of 0.1Pa). The module is slowly heated to 870°C at a rate of 60°C/h. The holding time (2~4h) depends on the effective size of the module. It can be kept at 0.8min/mm after the temperature is reached. The pressure in the heat preservation stage is controlled at 0.1~10Pa. When cooling, the furnace can be cooled in vacuum. When the temperature is lower than 500℃, it can be filled with 1×10 5Pa of high-purity N2 or a mixture of high-purity N2 and other reducing gases (such as H2) for cooling. Ensure that the surface of the module is free of oxidation and coloring. After annealing, the hardness of the module is less than 235HBW, and the structure is pearlite + uniformly distributed granular carbides.

Figure 3 Vacuum annealing process of H13 steel

(2) H13 die steel isothermal annealing process

The pressure of the vacuum furnace is 0.1~10Pa, slowly rises to 875~890℃ at ≤200℃/h and keeps it for 2~4h, then quickly cools to 710~740℃ and keeps it for 3~4h, then cools it to below 100℃ with high purity nitrogen gas.

(3) Cr12MoV die steel isothermal annealing process

The vacuum furnace pressure is 0.1~10Pa, slowly rises to 830~870℃ at ≤200℃/h and keeps it for 2~4h, then quickly cools to 720~740℃ and keeps it for 3~4h, then cools to below 100℃ with high-purity N2.

4. Vacuum carburizing of the mold

Vacuum carburizing is to heat the mold to austenitized state in a vacuum furnace, carburize in a carburizing atmosphere, and then diffuse and quench. Because the mold is heated in a vacuum state, the surface of the mold is very smooth and clean, which is suitable for the carburizing treatment of the mold with high surface quality requirements.

Example: Vacuum carburizing of 65Nb (65Cr4W3Mo2VNb) steel wire take-up connecting rod extrusion die.

(1) Carburizing medium (volume fraction): 70% CH4 + 30% H2. H2 is used as the diluent gas, and CH4 (methane) is the carburizing gas. The carburizing equipment is an internally heated small vacuum carburizing furnace. The mold vacuum carburizing process is shown in Figure 4.

(2) Service life. After the 65Nb steel mold is subjected to vacuum carburizing heat treatment, its service life is 2.5 times longer than that of the uncarburized mold, and 7.5 times longer than that of the Cr12MoV steel mold (conventional heat treatment).

Figure 4 Vacuum carburizing process of 65Nb connecting rod extrusion die

5. Vacuum carbonitriding of the mold

Vacuum carbonitriding is a chemical heat treatment process in which carbon and nitrogen are infiltrated into the surface of the mold under negative pressure in a vacuum furnace. Compared with single carburizing, the mold surface has higher hardness and better wear resistance. , It also has a certain degree of corrosion resistance and higher fatigue strength. Because the co-infiltration temperature is low and can be quenched directly after infiltration, the austenite grains are finer than single carburizing, so the core toughness of the mold is improved, the structure of the co-infiltration layer has no grain boundary oxidation phenomenon, and the performance of the mold is significantly improved.

Example: Vacuum carbonitriding of plastic molds made of 45 steel and quenched and tempered pre-hardened steel P20 steel (3Cr2Mo).

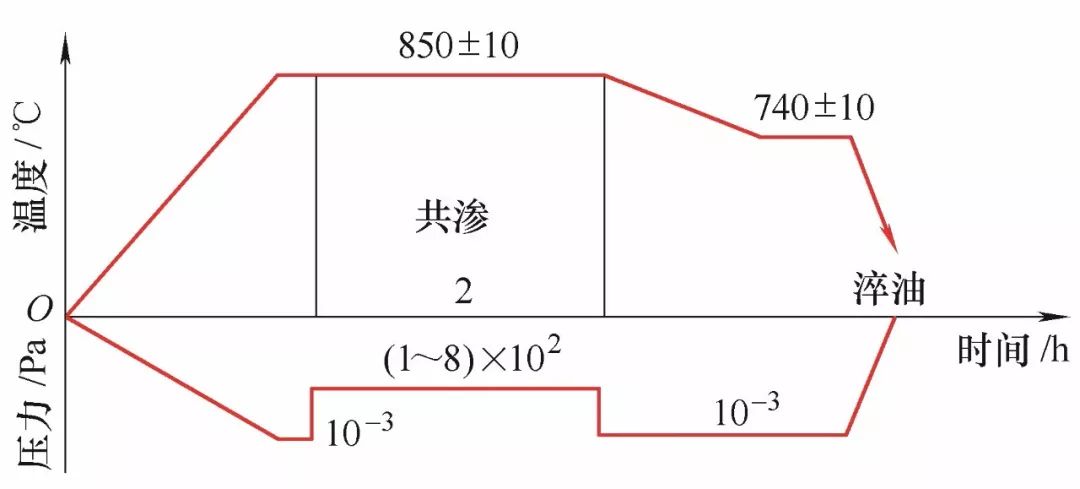

1) Using WZST-45 double-chamber vacuum carburizing and quenching furnace, the process curve is shown in Figure 5. The carbonitriding temperature is (850±10) ℃, pre-cooled to (740±10) ℃, and the oil is discharged after the temperature is uniform. For quenching, the pressure is 100~800Pa, and the co-penetrating agent is a mixture of acetylene and ammonia. Furnace installation: mold size 260mm×200mm×25mm, quantity 5 pieces; 240mm×180mm×20mm, quantity 5 pieces; 210mm×150mm×30mm, quantity 5 pieces. A total of 15 furnaces are installed, with a total mass of about 150kg.

Figure 5 Vacuum carbonitriding process of 45 steel and P20 steel mold

2) After 45 steel mold carbonitriding oil quenching, its appearance is uniform silver gray. The hardness of 45 steel and P20 steel molds can reach above 62HRC, which improves the surface hardness and enables P20 steel molds to enter a long life state. . The depth of the 45 steel carburized layer is 0.53~0.56mm, which helps to improve the service life of the 45 steel mold.

6. Vacuum pulse nitrocarburizing of the mold

Vacuum pulse nitrocarburizing retains the advantages of vacuum pulse nitriding, such as deep holes and blind holes with uniform inner wall infiltration, which has better wear resistance and seizure resistance than vacuum pulse nitriding, and has less white and bright layers and less brittleness. , The seepage layer is dense, the seepage speed is fast, and can withstand heavy loads and impact loads.

Example: Vacuum pulse nitrocarburizing of W9Cr4Mo3V steel cross groove punch.

(1) When the cross groove punch is working, it has to withstand the effects of large impact, compression, tension and bending stress, and the failure mode is the fatigue fracture of the groove. Originally made of T10 steel, after conventional salt bath heating, quenching and tempering, the average life of the mold is 30,000 pieces.

(2) The punch is made of W9Cr4Mo3V steel. After vacuum heating quenching, tempering and vacuum pulse nitrocarburizing, the die life is increased to nearly 300,000 pieces. Vacuum nitrocarburizing adopts ZCT65 double-chamber vacuum carburizing furnace, and the working vacuum is 2.7Pa.

1) Vacuum quenching and tempering process: 830~850℃×3min/mm preheating, 1080~1200℃×1~2min/mm heating, gas quenching and oil cooling; 540~580℃×1~2h vacuum tempering.

2) Vacuum pulse nitrocarburizing process: co-permeating agent composition (volume fraction): 50% C